Electric vehicles are now reaching a point where design choices carry more weight than ever before. Software plays a bigger part in performance. Regulations across regions have also been getting tighter now. Customers these days want vehicles that feel safe, respond well, and go farther on a single charge.

This change is pushing the modern engineering teams to rethink how they can design & test every part of their vehicles. Long cycles filled with repeated prototypes cannot support the speed or technical depth of current EV programs. Teams need tools that learn, predict, and react faster.

Two technologies are rising as the main drivers of this shift: AI powered Computer Aided Engineering, often called CAE, and Digital Twins.

Together, they give engineering groups a way to test more ideas, understand real life conditions better, and create vehicles that are lighter & safer at the same time.

Why Lighter Structures and Safer Systems Define the Next EV Wave

EV performance often depends on two core factors that are deeply connected to physics.

Weight

A reduction of mere ten percent in vehicle weight can stretch driving range by up to eight percent in real use. But reducing weight is not a simple material swap. Teams must do the following.

- Reduce mass in the structure without lowering crash strength

- Protect the battery pack from intrusion

- Keep stiffness high enough for handling

- Reduce part count when possible

These targets create trade offs that older CAE tools are slow to solve.

Thermal & Crash Safety

Battery packs bring new risks that were not present in earlier vehicle programs. These include thermal runaway, high voltage insulation concerns, floor deformation during impact, and long term fatigue around cooling areas.

Meeting these demands with older engineering methods leads to long cycles and unpredictable results. EVs need huge numbers of simulations that blend mechanical, electrical, and thermal behavior. AI powered CAE and digital twin systems are becoming the only practical way to meet these requirements.

How AI Powered CAE Changes Engineering Work

Traditional CAE relies on physics-based models and engineer-driven iterations.

AI powered CAE extends this by learning from simulation results and predicting outcomes faster.

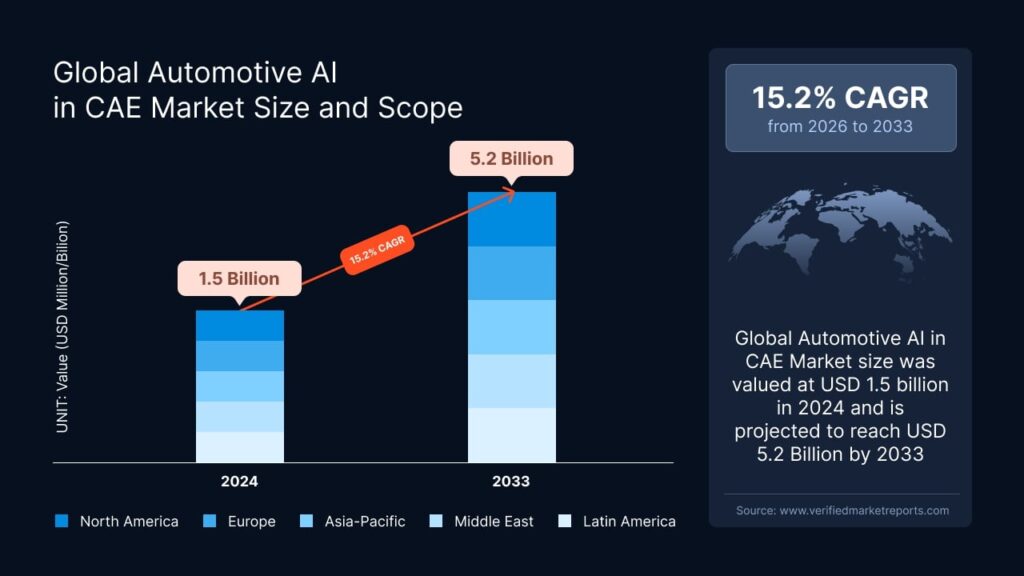

According to Verified Market Reports, the market for Automotive AI in CAE is projected to reach nearly $5 billion by 2033, growing from $1.5 billion in 2024, with a CAGR of 15.2% from 2026 to 2033.

What AI Adds

AI brings three main strengths that make modern EV programs more efficient.

- High speed predictions

AI models can estimate outcomes of complex physics in seconds. This makes it possible to test thousands of cases during early design phases.

- Generative design for lower mass

AI can create structure ideas that move load paths in new ways. Many of these shapes work well with casting, die casting and additive manufacturing.

- Early risk spotting

AI can find weak areas such as thin spots, stress clusters, battery tray flaws, and fatigue sensitive joints. This helps teams fix problems before spending time on detailed CAD work.

Impact on EV Programs

OEMs adopting AI powered CAE have seen reductions in prototype spending, shorter engineering cycles, and lighter structures. Testing becomes more predictable. Homologation is smoother because the design process produces cleaner data trails.

Digital Twins Bring Real World Behavior into the Design Cycle

AI makes simulation fast. A digital twin makes simulation a reality.

What Digital Twins Contribute

Better understanding of battery safety

Battery behavior shifts across climates, charge cycles, and usage patterns. A twin can track degradation, heat buildup, structural shifts, and cooling performance through life.

Lifetime validation of lightweight parts

Digital twins study fatigue, corrosion, energy absorption, and manufacturing deviations. This creates trust in lighter components before they go into production.

Smarter maintenance and software tuning

Field data from twins helps improve torque control, cooling strategy, cell balancing, and service planning. Warranty claims drop, therefore long term stability improves.

When AI Powered CAE & Digital Twins Work Together

In 2022, Hyundai Motor Group launched a pilot digital twin system to assess and improve the lifespan of EV, using real-world data for smarter software development. This program showed them the true value that a connected loop can produce.

Here are the benefits that other EV companies can also gain from this powerful combination:

1. Continuous Learning

- AI runs wide batches of simulations

- Field data updates the twin

- The twin compares predictions with actual results

- AI improves its predictions based on this feedback

Each cycle improves accuracy.

2. Faster crash and thermal testing

Crash cases that once took many hours can be estimated within minutes using AI models. Digital twin data keeps the results grounded in real conditions. Teams can explore hundreds of crash variations during early design stages.

3. Lightweighting with confidence

AI suggests lighter structures. The twin checks their performance over lifetime use. Only designs that pass both tests move forward. This removes the old tradeoff between safety and mass. EVs can now reach both goals at the same time.

Why These Capabilities Will Matter by 2030

Companies using AI-powered CAE & digital twins will gain huge advantage in timeline, cost and design maturity.

- Faster Programs: Development cycles can shrink by many months but using these technologies can speed-up the process

- Lower Production Cost: Better simulation accuracy reduces part count and speeds up tooling work

- Improved Safety: Digital twin data helps teams spot hidden risks before hardware is built

- New Data Opportunities: Twin driven insights open new service and update paths for OEMs

- Better Sustainability: Lighter designs help in reducing energy use

The Shift in Engineering Skills

As EV programs rely more on digital tools, engineering teams must learn to connect physical understanding with data-based tools.

Skills that combine simulation, materials, battery safety, and data handling will become more important.

Firms offering mechanical design engineering services already sit close to this shift, yet wider capability building will still be needed to keep pace.

The Road Forward

AI powered CAE and digital twins are quickly becoming the foundation of modern EV development. They make it possible to design parts that are lighter, stronger, and safer without long trial cycles. They bring field behavior back into early design choices. They lower risk in battery-related areas and improve prediction quality during early stages.

By 2030, the most competitive EVs would be the ones designed through this digital-first & data-driven approach. The shift has already started. The winners will be the companies that treat it as a strategic investment rather than a technical upgrade.