Every factory and operations team deals with the same problem: money is tight, customer demands keep growing, and something always slows down production.

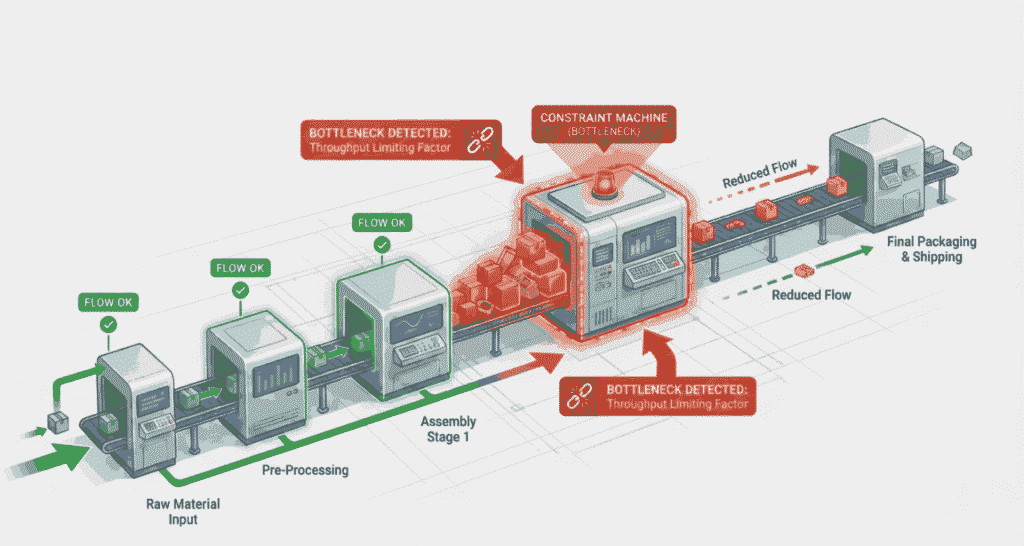

That something is called a bottleneck or constraint.

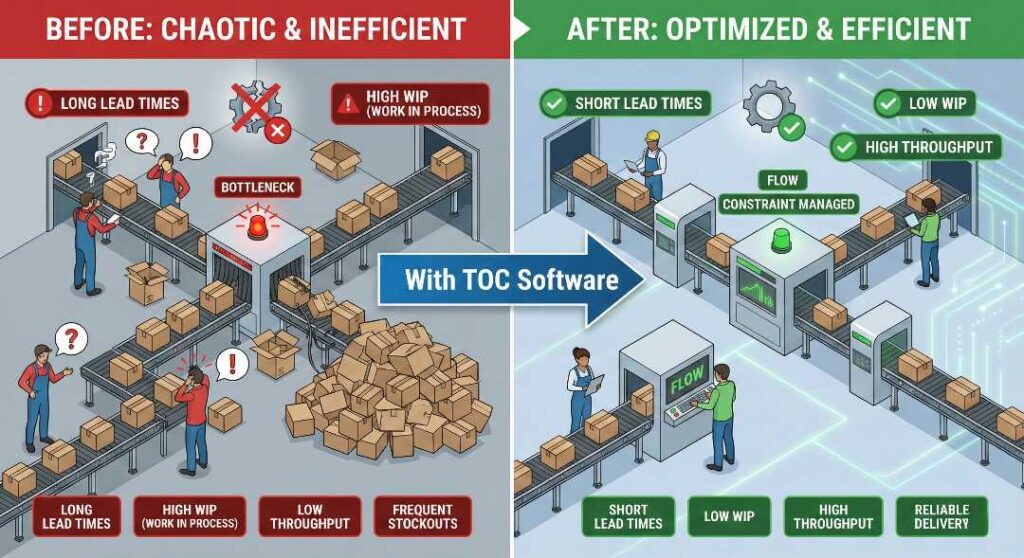

Most business leaders try to fix everything at once. They buy new equipment, hire more workers, and spend money on new technology. But here’s what they miss: only one thing is actually holding you back. Everything else is wasting your money and effort.

When you fix that one bottleneck, something amazing happens. Production goes up. Money sitting in inventory goes down. Delivery dates happen on time.

Theory of Constraints (TOC) software is a tool that helps you find exactly where that bottleneck is, measure how much it costs you, and fix it the right way.

In the world of Industry 4.0, where machines talk to each other and AI reads data all day and night, TOC software has changed. Today it combines real-time data from your factory, AI that learns from patterns, and smart systems that suggest fixes before problems even happen.

This guide shows you everything you need to know about TOC software. What it does. How it works. Why big companies like Ford and Amazon use it. And how you can use it in your operation.

What Is the Theory of Constraints?

Theory of Constraints is a way of running a business that was created by Dr. Eliyahu M. Goldratt, an Israeli physicist who became a business thinker.

Goldratt shared his idea with the world in 1984 through a book written as a story. The book is called “The Goal,” and he wrote it with Jeff Cox. In the story, a factory manager has 90 days to save his plant from closing. Using TOC ideas, he finds his biggest bottleneck, fixes it, and saves the whole operation.

The book became huge. Today it’s in 35 languages, and 7 million people have read it.

But what makes TOC so powerful?

The main idea is simple: every business has at least one thing that slows it down.

Think of your factory like a chain. You’re only as strong as your weakest link. That weak link could be a slow machine. It could be workers who don’t have the right skills. It could be an approval process that takes forever. It could be a supplier who can’t keep up.

Here’s the key insight: fixing anything except the bottleneck wastes your money and time.

If your bottleneck is a machine that can only make 100 units per hour, hiring 10 more workers doesn’t help. If your slow part is quality checking, buying faster equipment before it doesn’t help either.

TOC makes you stop wasting effort and focus everything on the one thing that really holds back your whole operation.

TOC uses three numbers to measure if you’re winning:

- Throughput – how much money your business makes by selling finished products.

- Inventory – how much money is stuck in materials, equipment, and products waiting to be finished.

- Operating Expense – how much it costs to run your business: wages, electricity, rent, fixes.

Most businesses try to spend less on inventory and operating expense. TOC says: make more money through throughput first. When throughput goes up, everything else gets easier to manage.

The Five Focusing Steps (POOGI)

TOC works because of a five-step process. The name is POOGI, which stands for “Process Of Ongoing Improvement.“

You do these five steps once. Then you do them again. Then again. This process never stops because your business is always changing.

Here’s exactly how it works:

Step 1: Identify the System Constraint

Your first job is to find the real bottleneck using facts, not guesses.

Look for these signs:

- Which piece of equipment or worker is busiest all the time

- Where does work pile up waiting to get processed

- Which step takes the longest time

- Which machine or person is the most overloaded

Real example: A car parts company thought their printing machine was the problem. They collected data. The real problem was the quality check step after printing. Fixing the printer did nothing. Once they made quality checking faster, production jumped.

Step 2: Exploit the Constraint

Once you find the bottleneck, squeeze everything out of it without spending money.

This step usually finds 20-30% more capacity that costs almost nothing.

Smart ways to do this:

- Remove tasks that waste the bottleneck’s time

- Don’t take breaks at the bottleneck during busy hours

- Always have material ready so the bottleneck never waits

- Check for bad work before it gets to the bottleneck

- Make the bottleneck the “heartbeat” that controls everything else

- Put your best workers on the bottleneck

- Only let important work go through the bottleneck; delay small projects

Example: A software team found that code review was their bottleneck. They added automatic testing before reviews and changed how they prioritize work. Throughput went up 35% without hiring anyone new.

Step 3: Subordinate Everything Else to the Constraint

This step is where most companies fail.

“Subordinate” means reorganizing your whole operation to protect and help the bottleneck. Every other department must follow the bottleneck’s pace and needs.

Key changes:

- Schedule other departments to supply the bottleneck without stopping

- If other departments finish early, have them wait instead of making extra material

- Line up all priorities around the bottleneck’s schedule, not individual team goals

- Always have backup material before the bottleneck so it never runs out

- Reduce material piling up after the bottleneck to free up cash

- Stop measuring other departments by how busy they are; measure them by how well they serve the bottleneck

Many companies don’t like this because it seems like other parts are “not working hard.” But that’s the point. Non-bottlenecks should have some idle time. If every part is working at 100%, you have multiple bottlenecks, and nothing moves smoothly.

Step 4: Elevate the Constraint

After you’ve squeezed everything out and reorganized (steps 2-3), if you still need more throughput, invest in adding real capacity to the bottleneck.

This is where you spend money. But only after you’ve used all the free improvements.

Ways to add capacity:

- Buy more machines or equipment

- Hire more people for the bottleneck

- Buy newer, faster technology

- Have other companies do some work outside

- Redesign the bottleneck to be faster

- Use Lean or Six Sigma methods to optimize the bottleneck

Example: After doing steps 2-3, Amazon needed fulfillment to move faster. Instead of hiring more people in existing warehouses, they built smaller warehouses closer to customers. This meant packages traveled shorter distances and cost less.

Step 5: Prevent Inertia from Becoming the Constraint or (Repeat the Process)

Here’s what happens: once you fix the first bottleneck, a new bottleneck appears.

This is automatic. Every system always has at least one bottleneck. The problem will move to the next weak spot.

This step means staying alert and moving back to Step 1 right away.

Many companies celebrate fixing their first bottleneck, get comfortable, and don’t notice their system has changed. Staying in POOGI means always looking for the next bottleneck and starting over.

Example: A project team fixed their approval process bottleneck. Six weeks later, they realized test data creation was now the bottleneck. They immediately used step 2 tactics to squeeze more out of that.

Key Features of TOC Software

Modern TOC software does the hard work for you. It finds bottlenecks, watches them in real time, and predicts problems before they happen.

Here’s what TOC software does:

Real-Time Bottleneck Finding

The software looks at your operation all day and shows you where work is piling up and which resources are overloaded.

Sensors on machines send data to the software. Your ERP system sends task information. The software connects all this data to find the true bottleneck, not just where you think it is.

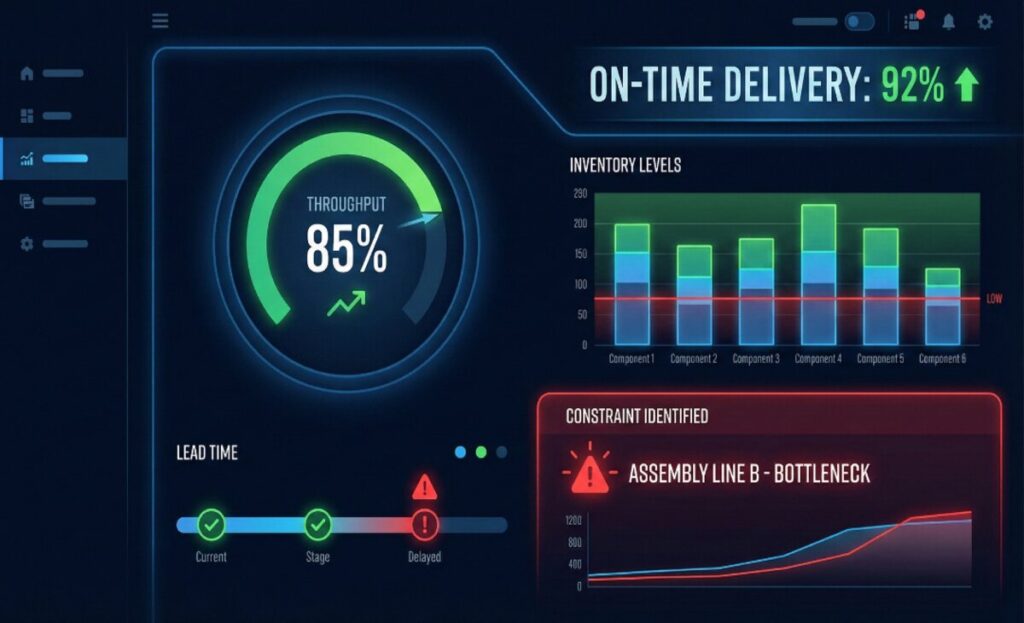

Throughput Dashboards You Can See

Screens show how your bottleneck is performing right now: how much it’s making, how busy it is, and what’s broken.

Most systems track these important numbers:

- OEE (Overall Equipment Effectiveness) – combines whether the machine works, how fast it runs, and if products are made right

- Cycle Time – how long one product takes from start to finish

- Lead Time – how long from when customer orders to when they get it

- First Pass Yield – percentage of work done correctly the first time

Visual Maps of Your Work

The software draws pictures of how your work flows, showing where bottlenecks are and how they affect everything downstream.

Smart software uses process mining to automatically draw these maps from your data, showing you what really happens (not what you think happens).

Drum-Buffer-Rope (DBR) Scheduling

DBR is a specific TOC scheduling method built into many platforms.

- Drum = your bottleneck’s pace (the rhythm that controls everything)

- Buffer = backup material before the bottleneck (prevents it from running out)

- Rope = a signal to stop releasing new work (prevents piling up)

The software automatically figures out how much backup material you need and when to release new work.

Predictions Before Problems Happen

AI-powered software predicts where bottlenecks will show up before they do.

By looking at past data, current trends, and customer demand forecasts, the system tells you: “In three weeks, the assembly line will become the bottleneck. Here’s what to do about it.”

This is powerful because it flips you from reactive (fixing after problems hurt you) to proactive (stopping problems before they happen).

Easy Connection to Your Existing Systems

Leading TOC software connects directly to what you already use: SAP, Oracle, Infor, or your custom system.

Data flows automatically, so your team sees real-time numbers without manual entry.

How AI Enhances TOC Software

Artificial intelligence is changing how Theory of Constraints works.

Here’s how:

AI Finds Bottlenecks Automatically

The old way: skilled people manually look at data and guess where the bottleneck is. The new way: AI does it automatically.

Machine learning systems look at hundreds of data points at the same time, finding patterns people would miss. The system learns from your unique operation and gets smarter over time.

Real example: Siemens used AI to predict project delays with 89% accuracy by looking at past projects and outside factors. This let them move people and resources before problems happened.

Real-Time Sensors Feed Live Data

Modern factories have thousands of sensors on machines, conveyor belts, and production lines.

These sensors send live information to TOC software: machine heat, production rate, breakdowns, material supply, quality results.

AI systems read all this information instantly, finding problems and bottleneck signals within seconds.

Real example: Avalign Technologies, a medical device company, installed AI machine monitoring and cut equipment downtime by finding and fixing bottlenecks within hours instead of days.

Predictions Based on Past Patterns

AI learns what bottlenecks look like and predicts where they’ll happen next.

It doesn’t just tell you “you have a bottleneck now.” It tells you “based on what’s happening now, your QA team will become a bottleneck in 14 days. Here’s the probability and what to do.”

This power lets you move resources and make decisions before a crisis hits.

AI Figures Out Why Problems Happen

When a bottleneck appears, AI automatically investigates the cause.

Using pattern matching and analysis, the system identifies why: Is equipment broken? Do workers need training? Is the process badly designed? Are products low quality? Is the supplier not keeping up?

Once you know the real cause, you can fix the right thing.

Digital Twins for Testing

A digital twin is a computer copy of your real operation that runs live.

TOC software uses digital twins to test what happens if you make changes: Add a machine? Change batch sizes? Reschedule work?

You test improvements in the computer world before you risk them in the real factory. This cuts risk and speeds up decisions.

Industry 4.0 Integration

Modern TOC software works at the center of Industry 4.0, connecting sensors, AI, robots, cloud computing, and data.

The system becomes the nerve center: sensors send data in, AI analyzes it, software suggests changes, managers approve, and systems make the changes automatically.

This turns TOC from a thinking process into an automatic improvement engine.

Business & Engineering Benefits

When companies do TOC software right, the results are real and measurable.

Production Goes Up 20-40%

By systematically removing bottlenecks, companies make more products without spending money in proportion.

Companies report that production jumps 20-40% in the first 12 months.

Delivery Gets Much Faster

Faster bottleneck cycles mean faster overall production. Work moves through your system quicker.

Delivery time often drops 30-50%, which means customers get orders faster and you can respond to demand changes quicker.

Less Money Sits in Inventory

TOC philosophy reduces work sitting on the floor by aligning how work enters with how fast the bottleneck can handle it.

Companies typically cut inventory by 15-30% while keeping or improving on-time delivery. Less money tied up means better cash.

You Hit Delivery Dates More Often

When work flows smooth and predictable, you make delivery dates consistently.

Most companies see on-time delivery go from 80-90% to 95-98%.

Operating Costs Drop

Less inventory, less wasted work, fewer emergency shipments, less waste, and better machine use all lower total operating costs.

Typical savings: 8-15% of total operating expense.

You Use What You Have Better

You don’t need to buy more or hire more. You use what you already have much smarter.

Non-bottlenecks run at 70-80% busy (which is healthy), while bottlenecks run at 95%+ busy. This is exactly what you want.

You Get Your Money Back

Companies usually see:

- Payback on software investment in 3-6 months

- Return on investment within 6-12 months

- Improved profit of 5-15% by year two

Real results:

- Ford Motor Company: Cut manufacturing time from start to finish by 40%

- Procter & Gamble: Got 5% more perfect orders and saved money on shipping

- Intel: Better production scheduling that produces more parts correctly

Top TOC Software Platforms in 2025

Several established software platforms lead the market:

ProModel (Simulation & Predictive Analytics)

ProModel is the industry standard for taking a real operation and simulating it to find where problems will happen.

You build a digital model of your operation in ProModel, test different scenarios, and predict bottlenecks before they hurt you.

What it does: Visual modeling of your process, finds optimization options, tests scenarios, gives detailed reports.

Best for: Factories, supply chains, delivery logistics, healthcare operations.

HARMONY (Strategy & Tactics)

Goldratt Research Labs (the company started by the TOC creator) built HARMONY as the official software for TOC thinking.

HARMONY helps your organization plan what to do, explain it to everyone, and execute the plan.

What it does: Maps out your strategy, plans execution, tracks continuous improvement, lets teams work together.

Best for: Company-wide TOC rollout, strategic planning, managing change.

Critical Chain Project Management (CCPM) Tools

Several companies make software that uses CCPM, which is TOC applied to managing projects.

These tools identify which tasks are critical, manage backup time, and handle resource limits in project networks.

Best for: Companies managing multiple projects, complex project environments.

Process Mining & Task Mining Platforms

Tools like Celonis, UiPath, and Signavio use AI to automatically discover what your workflows really are from system data, find bottlenecks, and suggest improvements.

What it does: Finds your real processes automatically, shows you where slowdowns are, finds root causes, suggests optimizations.

Best for: Service operations, IT help desks, finance departments, HR workflows.

Integrated ERP Systems with TOC Modules

Big ERP companies (SAP, Oracle, Infor, NetSuite) added TOC features: advanced planning, constraint-aware scheduling, accounting for throughput.

Best for: Large companies with existing ERP systems, operations across multiple locations.

TOC Software Comparison Table

| Software Platform | What It Does | Main Features | Who Uses It | How Hard to Set Up |

|---|---|---|---|---|

| ProModel | Simulation & Predictions | Visual process modeling, finding optimization options, scenario testing, detailed reports | Manufacturing, supply chain, delivery, healthcare | Medium |

| HARMONY | Strategy & Tactics | Maps out strategy, execution planning, tracks improvement, team collaboration | Company-wide TOC, strategic planning, managing change | Medium |

| CCPM Tools | Project Scheduling | Finds critical tasks, manages backup time, resource constraint planning, multiple project scheduling | Project companies | Medium-High |

| Process Mining (Celonis, UiPath) | Finds & Fixes Workflows | Automatically discovers processes, live monitoring, finds slowdowns, suggests improvements | Service operations, IT, finance, HR | Low-Medium |

| ERP-Integrated TOC | Enterprise Management | Constraint-aware scheduling, advanced planning, throughput accounting, system integration | Large companies, multi-location operations | High |

Real Companies Using Theory of Constraints

Here’s how actual companies use TOC:

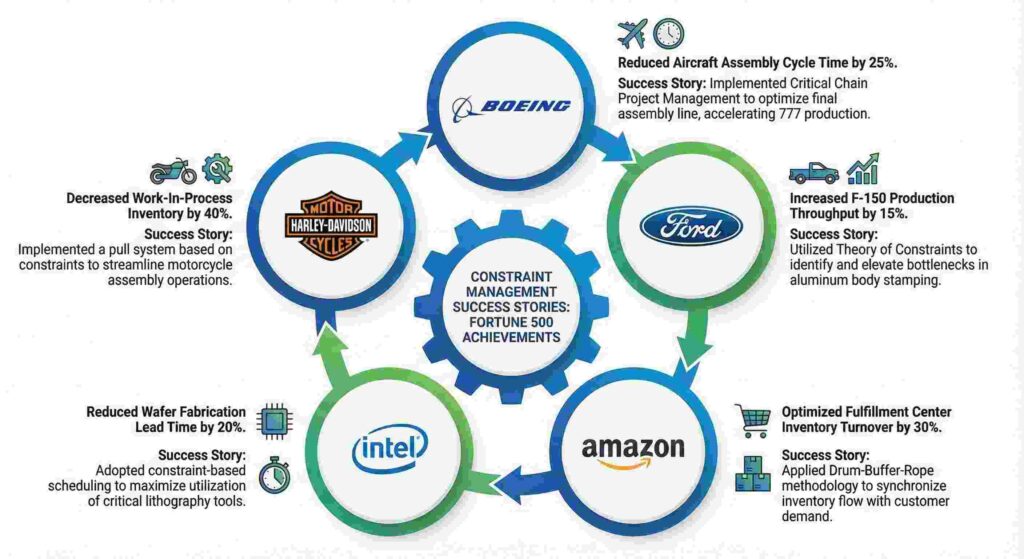

Boeing (Making Airplanes)

Problem: Complex supply chains, long production time, uneven workload across factories.

What Boeing did: Used TOC scheduling and constraint management to synchronize aircraft assembly, coordinating thousands of parts and suppliers.

Results: Cut production time by 25-35%, improved on-time delivery from 85% to 96%.

Ford Motor Company (Car Manufacturing)

Problem: Production bottlenecks across multiple plants, inconsistent delivery, high inventory.

What Ford did: Applied the Five Focusing Steps across engine and transmission plants to find and systematically fix bottlenecks.

Results: Cut manufacturing time by 40%, improved plant efficiency by 30%.

Amazon (Delivery)

Problem: Explosive growth, need to keep up with customer expectations, scaling fulfillment centers.

What Amazon did: Used TOC thinking for warehouse network design. They realized the real bottleneck was delivery distance. So they built many smaller warehouses close to customers instead of a few large ones far away.

Results: Enabled same-day and two-day delivery while controlling costs.

Intel (Computer Chips)

Problem: Chip manufacturing is expensive; every bottleneck costs millions. Need to make more chips per square foot.

What Intel did: Uses TOC in manufacturing scheduling, constraint management, and planning. They identify where equipment limits production and plan investments based on that.

Results: Made more chips per factory, cut production time, more consistent product delivery.

Dell Technologies (Custom Computers)

Problem: Making computers to order with short delivery times requires tight constraint management.

What Dell did: Applied TOC scheduling to their build-to-order system, finding bottlenecks in assembly, testing, and delivery.

Results: Kept delivery time at 3-5 days even with thousands of custom options.

General Electric (Multiple Industries)

Problem: Massive company with hundreds of factories; needs one improvement framework.

What GE did: Applied TOC across power generation, aviation, and industrial equipment factories.

Results: Better on-time delivery, less money tied up across multiple business units.

Procter & Gamble (Consumer Products)

Problem: Global supply chains, unpredictable retail demand, and the need for synchronized inventory.

What P&G did: Used TOC buffer management with retail partners. They use constraint identification to optimize the distribution network and inventory.

Results: 5% more perfect orders, more reliable delivery, and lower shipping costs.

3M (Thousands of Products)

Problem: Thousands of product types across multiple factories; complex material flow and decisions.

What 3M did: Used TOC thinking to identify system constraints in deciding what to make and production scheduling.

Results: Better production efficiency and lower costs from manufacturing complexity.

Harley-Davidson (Premium Motorcycles)

Problem: Quality consistency, scheduling with customization, dealer satisfaction.

What Harley-Davidson did: Applied TOC constraint management to assembly and supply chain synchronization.

Results: Better on-time delivery, consistent quality, and better dealer inventory.

Implementation Steps & Best Practices

Here’s a realistic roadmap for using TOC:

Phase 1: Foundation (Weeks 1-4)

- Check your current performance – Write down throughput, inventory, delivery time, on-time delivery rate, and operating costs.

- Find the bottleneck – Use data analysis, look at the factory floor, and interview managers.

- Get leader approval – Make sure executives understand TOC and commit to it.

- Pick software – Choose tools that fit your needs.

- Train the team – Teach staff the Five Focusing Steps and TOC thinking.

Phase 2: Quick Wins (Weeks 5-12)

- Exploit the bottleneck – Use low-cost improvements without capital investment.

- Reorganize other processes – Align non-bottleneck operations to support the bottleneck.

- Monitor weekly – Watch key numbers; compare to baseline.

- Tell people about wins – Share results across the organization.

Expected outcome: 15-20% production increase with zero capital spending.

Phase 3: Strategic Upgrade (Weeks 13-26)

- Decide on investment – Only invest after doing steps 2-3.

- Plan the investment – What equipment, hiring, redesign, or automation.

- Do it – Execute the plan.

- Watch for shift – Notice when the bottleneck shifts to the next weak point.

Phase 4: Continuous Improvement (Ongoing)

- Find the new bottleneck – Go back to step one.

- Repeat the five steps – Your organization now keeps improving.

- Use advanced software features – AI predictions, digital twins, and advanced analytics.

- Expand to other areas – Apply TOC to supply chain, projects, sales, and finances.

Best Practices

- Don’t jump to spending money. Most companies fail here. They see the bottleneck and immediately want to invest. Resist. Do steps 2-3 first; you’ll find 20-30% free improvement.

- Track the same metrics every week. Pick 3-5 key numbers (production, inventory, delivery time, on-time delivery, operating cost). Track them weekly. Don’t change how you measure mid-project.

- Celebrate and communicate. Share wins frequently. TOC changes how an organization thinks; visible progress keeps momentum.

- Change how people are paid and measured. If each department is still measured by how busy it is, they’ll fight against the constraint-first approach.

- Use software as a tool, not as a solution by itself. The real work is thinking, deciding, and taking action. Software gives you information; you make decisions.

- Expect the bottleneck to move. This isn’t a problem you solve once. You repeat forever. This is actually good news because it means you keep improving.

Case Study: Real Factory Transformation

Company: Mid-size car parts supplier (850 workers, $120 million yearly sales)

Starting Problems:

- Production time: 8-10 weeks

- On-time delivery: 82%

- Inventory cost: $18 million

- Profit: Not growing despite more sales

How They Did It:

Week 1: Found the bottleneck: a CNC machine at 98% busy while other equipment ran at 60-70%.

Weeks 2-8 (Exploit phase): Used quick fixes: faster die changes, quality checks before the machine, and non-stop operation with rotating breaks. Production jumped from 240 to 310 units per week without spending money.

Weeks 9-16 (Reorganize phase): Other departments synchronized their output to match the machine’s pace. Total inventory dropped from $8 million to $5.2 million.

Weeks 17-26 (Invest phase): Bought a second CNC machine ($950,000). Production climbed to 480 units per week.

After 12 Months:

- Production time: 4-5 weeks (50% faster)

- On-time delivery: 97%

- Inventory: $12.5 million ($5.5 million freed up)

- Profit: +8% better margins

- Return on investment: 340% in year one

Frequently Asked Questions

Conclusion

Theory of Constraints software transforms how operations leaders manage bottlenecks, production, and profitability.

The methodology, created by Dr. Eliyahu Goldratt, has proven itself at Fortune 500 companies in aerospace, cars, chips, delivery, and consumer products.

In 2025, AI-powered TOC platforms remove guessing from bottleneck finding, enable predictions, and automate improvement cycles.

The proven process:

- Find your real bottleneck

- Squeeze everything from it with no capital

- Reorganize everything else to support it

- Only then invest in adding capacity

- Prevent inertia and repeat

Result: 20-40% production gains, much lower inventory, faster delivery, and measurable return on investment within months.

Next Steps:

- Audit your operation’s top five bottlenecks

- Bring together your leadership team and walk through the Five Focusing Steps

- Pick TOC software that fits your situation

- Run a small test in one production line or area

- Watch results, share progress, and expand

The bottleneck limiting your operation right now won’t go away by itself. But with TOC software and consistent execution, you can systematically eliminate it—and the dozens of bottlenecks that come after.

That’s how world-class operations are built.