Engineering education has always been about blending theory with practice. While textbooks teach the fundamentals of mechanics, design, and materials, it’s hands-on experience that prepares students for the real world. Modern classrooms are evolving, and Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) have become essential to that shift.

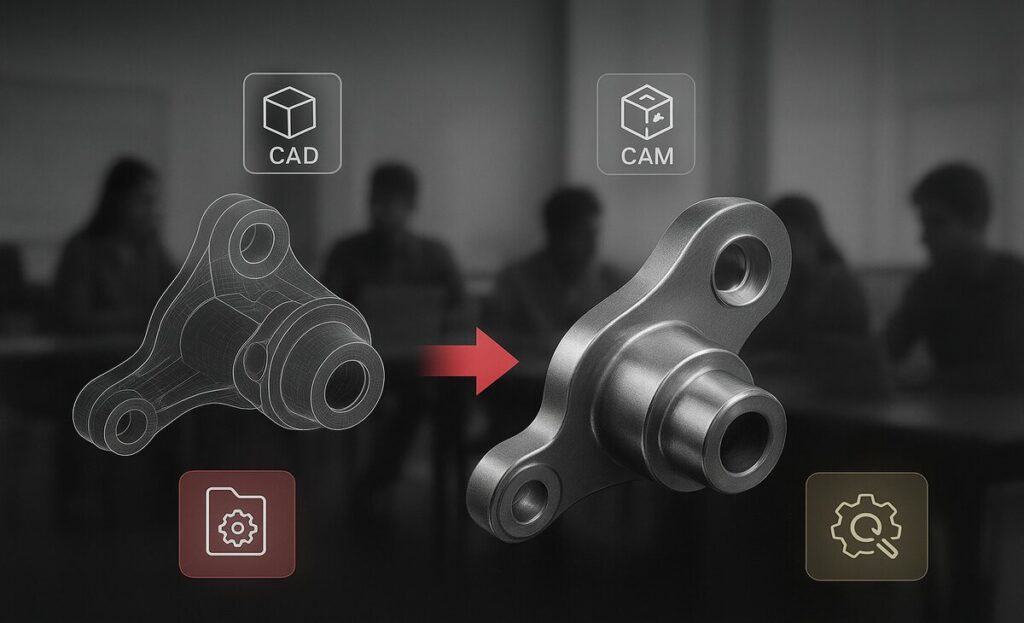

Visual CAD/CAM allows students to see the complete journey of a product, from digital design on a screen to the final manufactured part. Instead of learning concepts in isolation, they understand how design decisions directly affect manufacturability, costs, and efficiency.

Today’s industries expect graduates to walk in with practical digital skills. Employers look for engineers who can design, simulate, and manufacture with speed and accuracy. By embedding CAD/CAM into the curriculum, educational institutions ensure students don’t just learn about engineering; they actively practice it.

Key Benefits for Students

For students, Visual CAD/CAM offers much more than software familiarity. It provides an early taste of what it’s like to be an engineer in a digital-first industry. Some standout benefits include:

- Hands-on learning – Students design components, simulate how it will be machined, and receive immediate feedback on their ideas.

- Job readiness – By working on real projects, students graduate with portfolios that showcase practical skills, giving them an edge in competitive job markets.

- Collaboration & teamwork – CAD/CAM projects often mirror real-world team dynamics, where designers, engineers, and machinists must collaborate to achieve results.

- Problem-solving mindset – Students learn to optimize designs for materials, costs, and production speed, sharpening their critical thinking.

Engineering programs that embrace CAD/CAM teach students not only what to think, but how to think like engineers, preparing them to transition smoothly into industry roles.

Advantages for Educators & Institutions

While students benefit directly, educators and institutions also gain when Visual CAD/CAM becomes part of the learning environment:

- Bridging academia and industry needs – By aligning curricula with industry practices, educators prepare students for the skills companies actively demand.

- Enhanced teaching outcomes – Demonstrating concepts visually and interactively keeps students engaged and makes complex topics easier to grasp.

- Opportunities for research & innovation – Professors can apply CAD/CAM tools in prototyping, cross-disciplinary projects, and advanced research, enriching both teaching and publication opportunities.

- Institutional reputation – Universities that produce CAD/CAM-trained graduates stand out, making them more attractive to both students and industry recruiters.

In short, CAD/CAM helps institutions future-proof their engineering programs, ensuring graduates are academically strong and industry-ready.

Real-World Applications in Academia

The impact of CAD/CAM in education goes beyond labs or lectures. It is already shaping how universities and colleges run projects, labs, and competitions. Some typical applications include:

Architecture and Design Studios

Students use CAD tools to develop building concepts, then rely on CAM processes like CNC milling or 3D printing to create scaled prototypes.

Mechanical Engineering Workshops

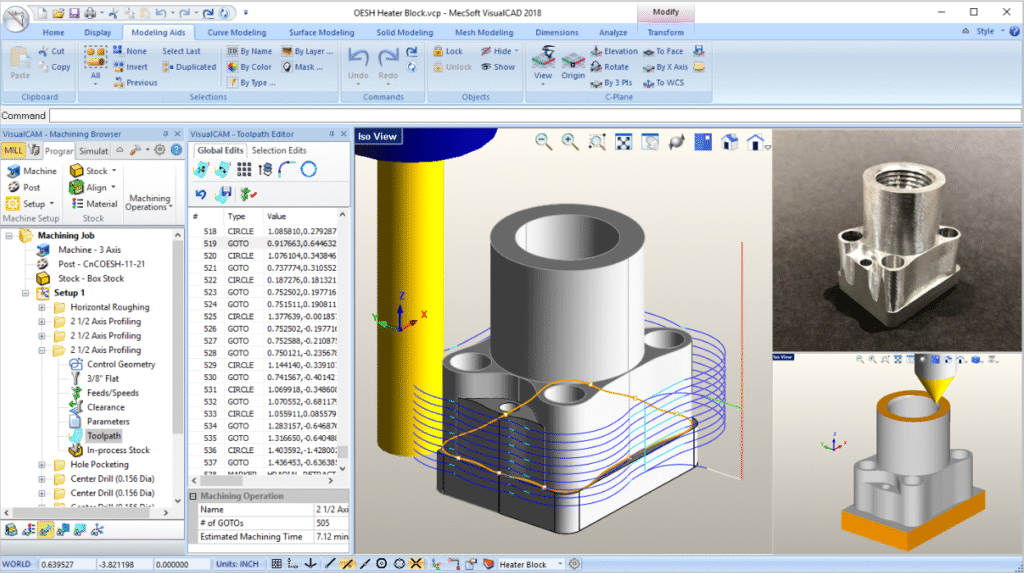

Labs increasingly combine CAD modeling with CNC machining, allowing students to design parts digitally and see them manufactured on the shop floor.

Turnkey CAD/CAM Labs

Some institutions are turning to ready-to-use CAD/CAM lab packages, where CNC machines come pre-configured with professional CAM software. For instance, MecSoft’s collaboration with CNC Masters offers educators a complete, plug-and-play solution, ensuring students spend more time learning and less time troubleshooting setups.

Student Competitions

From Formula SAE race cars to robotics and aerospace challenges, CAD/CAM is at the heart of student-led projects where design-to-production efficiency often determines success.

Capstone & Final-Year Projects

Many institutions encourage final-year engineering students to solve real-world problems. CAD/CAM software gives them the flexibility to experiment with prototypes, refine designs, and deliver professional-quality outputs.

In fact, many institutions worldwide now integrate professional Visual CAD/CAM solutions into their labs to give students industry-level exposure. By working on the same kind of software and processes that manufacturers use daily, students graduate not just with knowledge but with practical experience that employers immediately value.

The Future of CAD/CAM in Education

As industries undergo digital transformation, the role of CAD/CAM in education will expand even further. Key trends include:

Integration with AI and Automation

Future CAD/CAM platforms are increasingly powered by artificial intelligence, allowing students to explore generative design, automated toolpath optimization, and error detection. This prepares graduates for Industry 4.0 and beyond.

Cloud-Based Access

Instead of being tied to a single computer lab, cloud-based CAD/CAM makes it possible for students to collaborate from anywhere. This expands access to tools and promotes remote teamwork, which is an essential skill in today’s global engineering projects.

Cross-Disciplinary Expansion

While CAD/CAM has been a staple in mechanical and manufacturing courses, it is now gaining ground in biomedical engineering, civil infrastructure, energy systems, and even product design.

Industry Partnerships

More universities are collaborating with software providers and manufacturers to give students direct exposure to real-world tools, internships, and projects.

Ultimately, the future belongs to engineers who can move seamlessly from digital design to digital manufacturing. Embedding CAD/CAM deeper into curricula, educational institutions ensure that their graduates not only keep up with change but also lead it.

Conclusion

CAD/CAM is no longer an optional add-on in engineering education, it has become a core skill set that bridges the gap between classroom theory and industrial practice. It builds confidence and employability for students and helps educators keep curricula relevant in a fast-changing industry. Most importantly, it equips the next generation of engineers to design, innovate, and manufacture with precision. By embedding CAD/CAM into education today, we are preparing graduates to lead tomorrow’s engineering breakthroughs.